With around 550 employees, Touratech produces a large part of its current product range at its Niedereschach site. And that's not all: high-quality accessories for premium brands such as BMW Motorrad are also manufactured in the modern production facility. Let's take a look inside the factory halls.

Sharp edges, shiny aluminium, technical-looking plastic, add-on parts made of elegant, gleaming stainless steel – around 200 individual parts come together to form a highly functional unit with a state-of-the-art design: the BMW Adventure case.

DEVELOPMENT AND MANUFACTURING FROM A SINGLE SOURCE

The BMW Adventure case is a typical example of OEM manufacturing at Touratech. The abbreviation stands for Original Equipment Manufacturer, i.e. supplier of original equipment. However, the cooperation between BMW and Touratech is not limited to contract manufacturing. In a tender process, Touratech won with a visually and technically exceptional design proposal, not only securing the production of this modern aluminium case but also developing the product to series production readiness in close cooperation with BMW Motorrad.

FROM ALUMINIUM SHEET TO HIGH-END CASE

So far, we have learned: the BMW Adventure case has nothing in common with the aluminium boxes that globetrotters screwed onto their bikes 30 or more years ago. Instead, it is a complex luggage system with an extensive range of functions, including electrification of the left pannier, which allows gadgets such as smartphones, tablets or laptops to be charged in the water-protected interior. Let's now try to trace the journey from raw material to finished product. Even though a whole host of other materials are now very important, aluminium remains the key material for the BMW Adventure case.

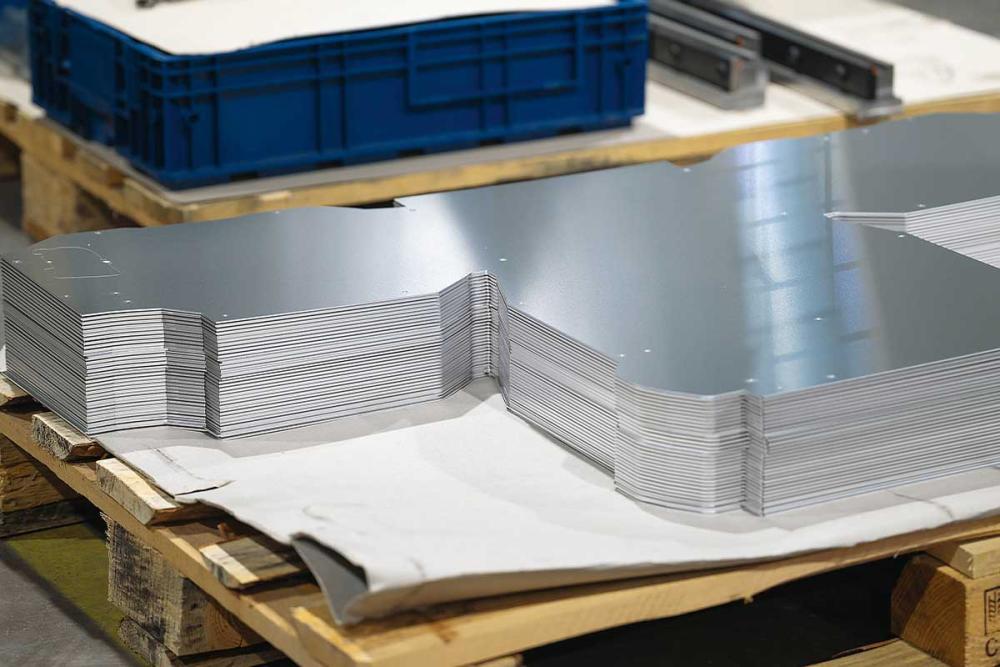

With the help of robots and CNC-controlled machines, large aluminium plates are used to create the base plate for the case shell. This is folded and embossed before it makes its way to the case assembly line.

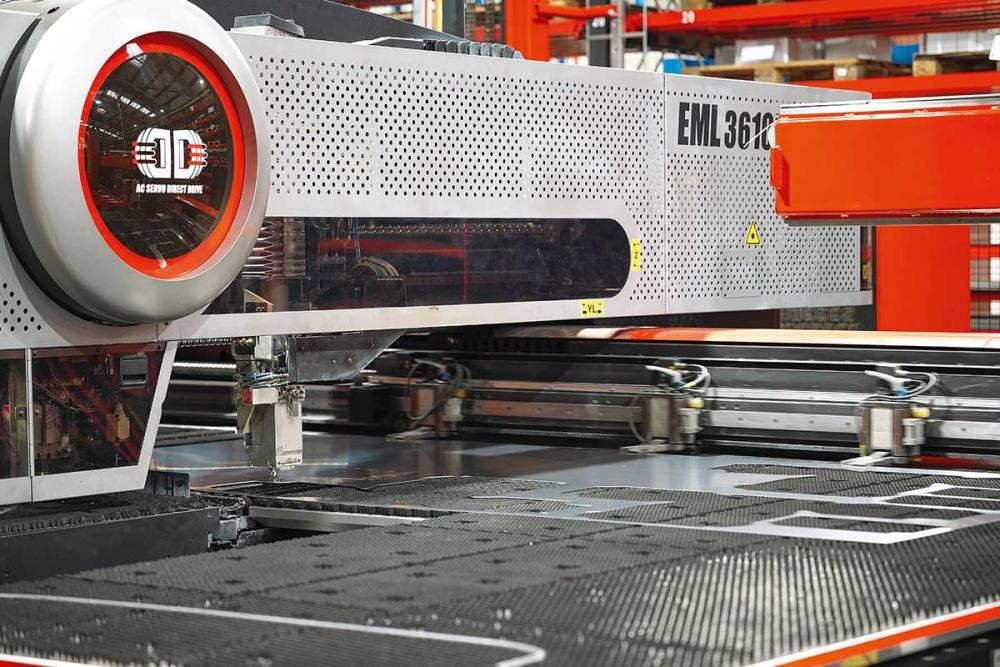

FULLY AUTOMATIC: THE SHEET METAL WAREHOUSE

And there is aluminium galore in the Touratech sheet metal warehouse. The raw material is stored in huge high-bay racks. But where is the right plate for our aluminium case? ‘We have “chaotic warehousing” here,’ says Viktor Kerlach, Production Manager responsible for ‘sheet metal and tubing’. This could be described as Touratech's core department, as this is where all the preliminary products for the most important parts are created. ‘However, “chaotic” is not meant negatively in this context,’ says Kerlach. ‘Other terms are “dynamic warehousing” or “free space system”, which simply means that material is stored wherever there is space available. This allows us to make optimum use of the available capacity.’ For the system to work, it is of course necessary for the warehouse clerk to enter the exact storage location of the respective material into Touratech's own ERP system when storing it. This data enables the state-of-the-art CNC machines to access the required material via a fully automatic sheet metal feed. In the case of our BMW Adventure case, this is a 1.5-millimetre-thick sheet of a precisely defined aluminium alloy.

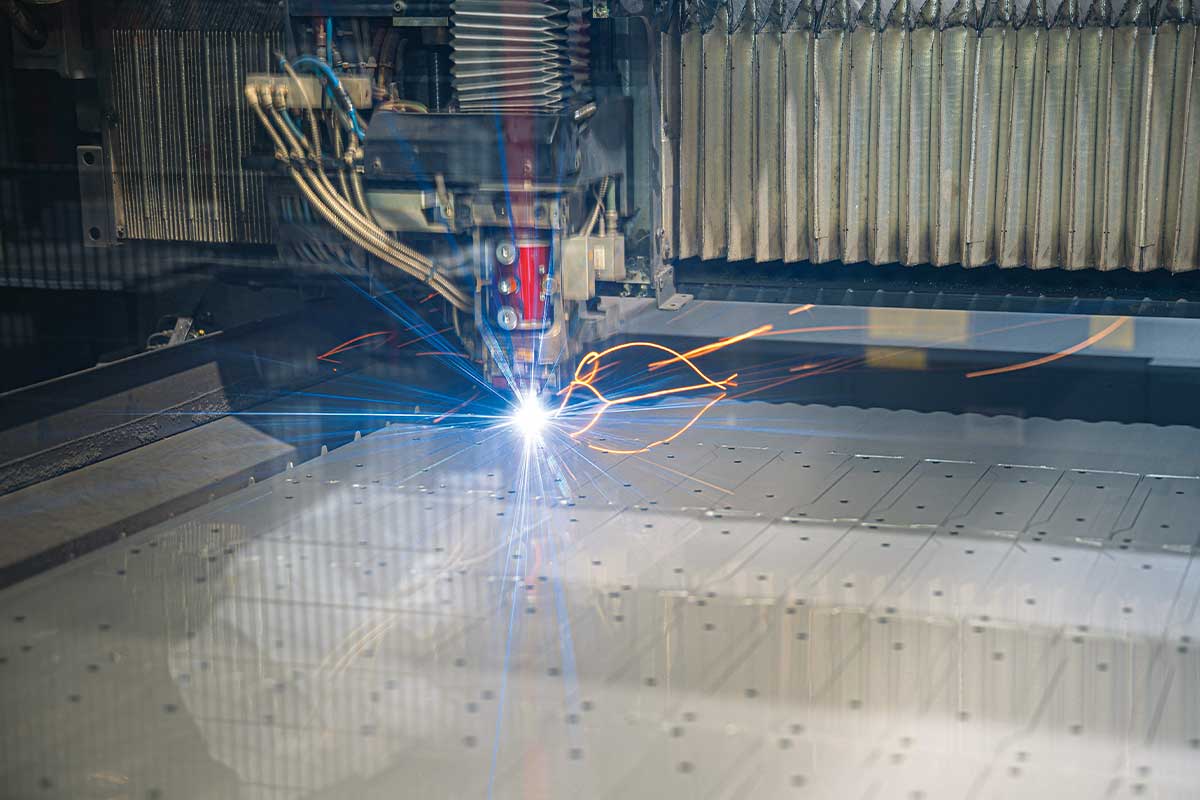

LASER PRECISION: THE FIRST CUT

In the first step, the machine uses a laser to cut a plate out of the sheet metal. Aluminium is not only a particularly high-quality material due to its high strength and low weight, but also an expensive one. This is partly due to the enormous amount of energy required to extract it. ‘For Touratech, using raw materials as sparingly as possible is not only economically necessary, but also in line with our ecological responsibility,’ says Viktor Kerlach. Next to the CNC laser machine, there is a pile of aluminium structures riddled with holes. The 44-year-old industrial foreman lifts one of them up. All that remains of an aluminium plate are a few bars and tiny areas. ‘Our workpieces are automatically nested so that as little aluminium as possible is left over, which will of course be 100 % recycled,’ explains Kerlach.

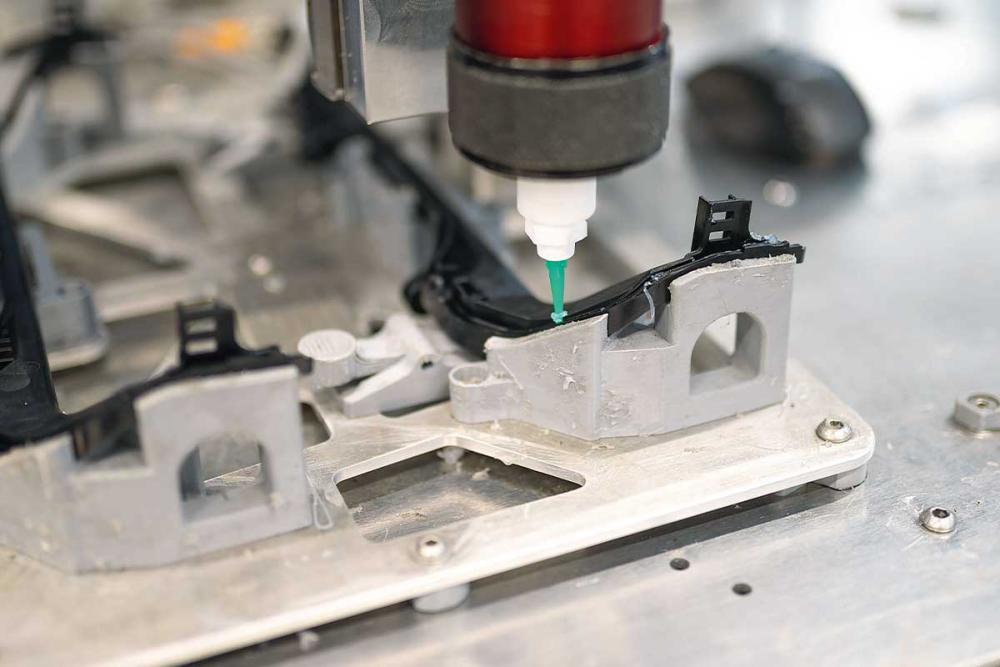

Plastic and aluminium are bonded together.

KEYWORD: AUTOMATION

The steps involved in the assembly of the case require a lot of manual work by qualified employees. However, as in many other areas of production, Touratech is replacing monotonous and error-prone work steps in case assembly with automated solutions. As part of the automation process, for example, a robot is used to precisely apply adhesive to the seam that connects the cover plate to a plastic element. This allows higher quantities to be produced while also achieving an even higher level of quality.

The sensitive surfaces require the utmost care.

THE THIRD DIMENSION

Now the circuit board, the first component of our BMW Adventure case, begins its journey through production. It is bent and embossed, and step by step, a flat piece of sheet metal is transformed into a three-dimensional blank for the case shell. This is packed into a box with numerous identical workpieces and sent to an external service provider, who processes the surface and finally anodises it. Back at Touratech, the next stop is KoMo. As you might guess, this internal abbreviation stands for case assembly (Koffermontage). The organisation of this important department at the Niedereschach site is far less simple.

STRICT DOOR: THE INCOMING GOODS INSPECTION

But before entering KoMo, there is a strict inspection. Regardless of whether they are our own preliminary products, those from sister companies of the Happich Group or purchased parts, every single part must pass the incoming goods inspection. Of course, the anodised blank for the case shell is carefully wrapped in foil. Nevertheless, minor damage can always occur during transport. If one of the case shells does not meet the strict quality specifications defined jointly by BMW Motorrad and Touratech, it is sent back to the anodiser, who sands down the defect if possible and then re-anodises the surface.

AN INGENIOUS COMBINATION: ALUMINIUM AND PLASTIC

Once the blank has passed the strict incoming goods inspection, it is diligently recorded and transferred to the KoMo warehouse. The next stage is shell production. The shell of the BMW Adventure case is a complex construction made of aluminium and high-quality plastic. Our blank is now connected to the plastic components. To do this, a special adhesive is first applied, then the rear wall is screwed to the shell blank. This unit is baked at high heat for a precisely defined period of time. Quality specifications were also defined for this sensitive process as part of the joint development contract. For optimum strength of the case, additional stiffening plates are now riveted on, and the right-hand case is fitted with a heat shield to protect it from the heat radiation of the rear silencer. The aluminium-plastic composite is characterised by excellent strength values, which were intensively tested and confirmed during the development process using shaker tests. In a similar process, an aluminium pre-product is connected to a plastic element to form the case lid.

PIECE BY PIECE: THE ONE-PIECE WORKFLOW

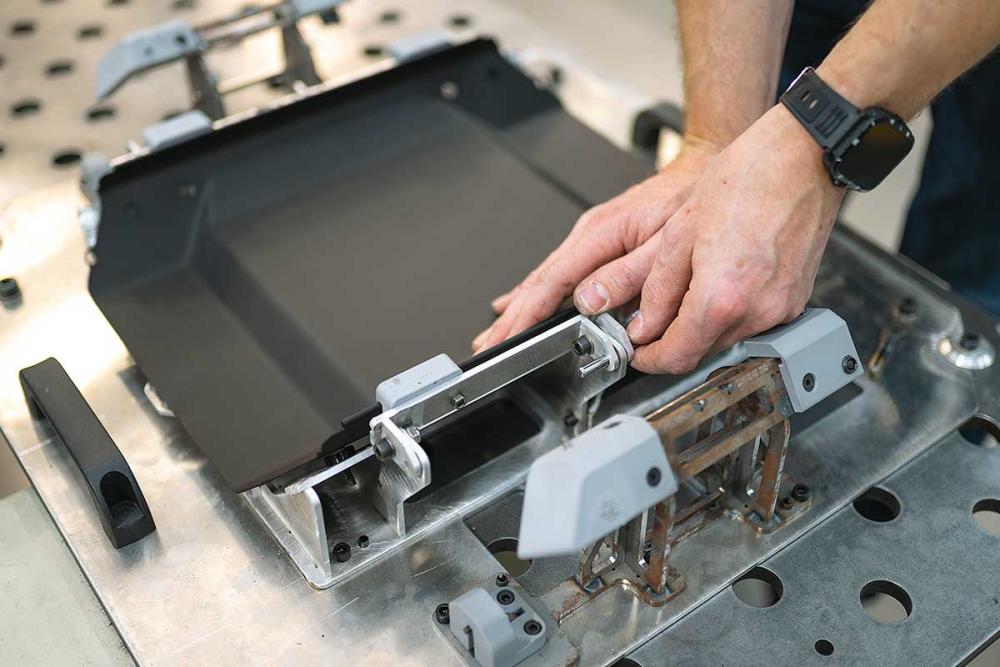

Precise fixtures from our own production for maximum dimensional accuracy

Once the case shell has cooled down after leaving the oven, it is fed into the so-called line. Here it encounters numerous components that have been assembled in a separate sub-department, the pre-assembly department; these include, for example, the case lid or the locking mechanism, the interior lighting and countless other individual parts. All preliminary products and components are conveniently stored on shelves behind the workstations. The complete cases are assembled at nine final assembly tables. ‘In contrast to assembly line production, where only a single, always identical work step is carried out at each station, we rely on a one-piece workflow for Touratech case assembly,’ explains Michael Gnädig, production manager at Touratech. ‘This means that the colleagues involved are proficient in all work steps and assemble a case completely from pre-assembled components and other individual parts. And they are also responsible for “their” case. This approach creates a particularly high level of quality awareness among the workers.’

STRUCTURED: THE TOURATECH WORKER GUIDANCE SYSTEM

The state-of-the-art worker guidance system ensures consistently high product quality

In order to guarantee the extremely high quality standards that BMW Motorrad's discerning customers rightly expect, Touratech has established a state-of-the-art, self-developed worker guidance system. All steps of the assembly process are stored in this system. In addition, each case is equipped with an RFID card that accompanies it through all steps from the beginning to the end of production and makes it uniquely identifiable. When a worker wants to start assembling a case, they log in with their personal chip and the system guides them through all the work steps. To facilitate training, explanatory graphics or videos for each work step can be called up on a small screen directly at the workstation. Experienced workers can book several assembly steps at once, but quality control steps must always be booked separately. The same applies to screwdriving steps, which must be confirmed individually with the personal chip. The key feature here is that the tool, for example a screwdriver, is automatically adjusted to the torque and number of revolutions required for the work step. If a problem occurs, it can be reported directly to the work preparation department or shift management. Those responsible receive a message on their smartwatch in real time and can take immediate action. Only when a step has been completed correctly does the system move on to the next work step. Once the case has passed through final assembly, the data package collected during the process is transferred to the end-of-line inspection. There, it is automatically evaluated to determine whether all specifications have been met.

The complex end-of-line inspection comprises over 100 test steps

LEAVING NOTHING TO CHANCE: END-OF-LINE CHECK

The complex end-of-line check is no less important than careful assembly. In close cooperation with the customer, Touratech has developed 104 test criteria that the finished case must meet. The complex procedure takes up to 10 minutes for each individual case. As part of this structured process, seemingly trivial details such as the presence of all rivets are checked, as are the gap dimensions. Compliance with operating forces is also subject to final inspection, as are the continuity of the silicone seams, the functionality of the mounting mechanism and the top case central locking system. Gauges and sophisticated testing devices assist employees in their responsible work during final inspection. If they approve the case, it is given a QR code so that every step of the process can be traced.

READY FOR GREAT ADVENTURES

An inconspicuous aluminium plate, which was just one of tens of thousands in Touratech's automated sheet metal warehouse, has been transformed into an attractive BMW Adventure case. It is now carefully packed and shipped by Touratech Logistics to the BMW accessories warehouse. And then it's finally time to set off on a great adventure with its new owner.

THE CASE FOR THE BMW R 1300 GS ADVENTURE – MADE BY TOURATECH

With a volume of 36.5 and 37 litres respectively, the Adventure cases offer storage space of over 73 litres. With practical details such as an integrated USB-C charging port, up to 10 kg of payload per side and enough space for a helmet, they are ideal even on the longest journeys. A separately available volume extension increases the capacity of the left and right cases by 10 litres each. The volume extension is attached between the shell and lid of the cases and is securely connected to the cases by the BMW locking system.