Touratech consistently relies on „Made in Germany“. Short delivery routes, the transparency of supply chains and manufacturing processes as well as a first-class supply of skilled workers in the region are just some of the reasons for this sustainable business decision.

Touratech continuously invests in the Niedereschach site to ensure state-of-the-art production processes and smooth logistics. The machine tools and machining centres used by Touratech are among the best and fastest on the market. A total of 11 welding robots are used in Touratech production (as of 11/2023) to weld aluminium or stainless steel constructions. A fully automated sheet metal warehouse works seamlessly with three automatic laser and punch-laser combination machines. State-of-the-art production planning and control (PPS) ensures optimum machine utilisation and thus contributes to cost-effective production. A logistics building equipped with the latest high-bay technology enables rapid delivery of all Touratech products to distributors and customers worldwide.

Touratech is the development and manufacturing partner for the BMW Motorrad Vario luggage system

Apart from the material, the Vario luggage system from BMW Motorrad has little in common with conventional plastic cases. The cases have interior lighting, radio remote control for the locking mechanism using the vehicle key and - an absolute world first - infinitely variable volume adjustment. In a challenging tender, Touratech was not only chosen as the partner for the series production of the system, but also for its development. Touratech‘s developers set new standards with numerous innovative solutions, such as the toothed belt-driven volume adjustment.

Touratech implemented a highly standardised and transparent production process in order to manufacture the sophisticated technology in series at a consistently high level. Instead of a classic assembly line, the cases are completely assembled step by step by one or two employees in a „one-piece flow“ after pre-assembly. To ensure maximum process reliability, Touratech has implemented an advanced worker guidance system in which all steps of the assembly process are stored. In addition, each case is equipped with an RFID card that accompanies it from the beginning to the end of production and makes it clearly identifiable.

To make training easier, explanatory graphics or videos for each work step can be called up on a small screen directly at the workstation. For important work steps, such as screwing, the screwdriver is automatically adjusted in terms of torque and number of revolutions.

Once the case has passed through final assembly, the data package collected during the process is transferred to the end-of-line control and evaluated. If all values are within the target range, a robot designed by Touratech‘s sister company Moldes Epila tests all mechanical and electrical functions of the Vario case with maximum repeat accuracy.

Touratech is the development and manufacturing partner for the BMW Motorrad Adventure pannier

In addition to manufacturing for the huge product portfolio under its own brand, Touratech has been an important supplier to the motorbike industry for three decades. Premium brands such as BMW, Ducati and KTM rely on the proverbial Touratech quality and have products for their original accessories programme manufactured at the Niedereschach site. And that‘s not all: in addition to manufacturing, Touratech also takes on the complete development on behalf of its customers.

A prominent example: the aluminium case system for the BMW R 1300 GS Adventure. From the unique locking mechanism and the complex structure of the robust body to the electrification, Touratech has developed the state-of-the-art solution in this segment for BMW Motorrad.

Around 150 colleagues produce up to 1,650 aluminium cases per week for BMW Motorrad in three shifts on a dedicated assembly line. Intensively trained employees work closely with state-of-the-art robot technology in a computerised workflow that guarantees a consistently high level of quality.

The comprehensive end-of-line inspection, which every single case undergoes before it leaves the factory, comprises over 100 criteria. The ultra-modern Touratech logistics system ensures that the cases arrive at BMW carefully packed and on time.

Pannier production

In addition to the know-how gained from over 30 years of aluminium case construction, state-of-the-art machinery is the second important pillar for the legendary quality of ZEGA aluminium cases. The handling of the raw material is fully automated to prevent damage to the surfaces. The aluminium sheets are cut exclusively by laser. This applies to the shell material, which is cut using state-of-the-art flatbed lasers to ensure precise external geometries and hole patterns, as well as to the drawn bases and lids, which are cut precisely using a 3D laser after forming.

Just as the work steps for processing the formed parts are bundled in an interlinked and fully automated processing cell, the most important steps for manufacturing the case shell also take place in an automated processing centre.

Despite the high degree of automation, numerous qualified employees are required in case production. This applies to the operation and monitoring of the machining centres as well as the assembly of the individual components.

Maximum precision is required when assembling the sophisticated design. To ensure that nothing goes wrong despite intensively trained employees, Touratech production has a tightly meshed quality control system.

32 employees work in two shifts in the actual case production, and around 130 colleagues if the production of the carriers and add-on parts is included.

It is not only Touratech customers who benefit from the company‘s unique expertise in the development and production of high-quality aluminium motorcycle cases. Numerous premium manufacturers such as BMW, Ducati and KTM have Touratech manufacture cases for their own original accessories range. A total of around 100,000 cases leave the factory in Niedereschach every year.

Seats production

From the seat pan to the model-specific foam core to the application of the cover, Touratech seats are manufactured with craftsmanship and modern technology.

Maximum precision is already required during the development of the seat pan, where the model makers create a so-called master sample by hand, on the basis of which the mold for series production is built. Touratech uses the proven resin injection molding (RIM) process for the seat pan. In this process, two components of a synthetic resin are mixed and injected into a mold, where they quickly harden.

The quality of the foam core is essential for the comfort of a motorcycle seat. The experts have invested countless hours in the development of foams. The exact mixing ratio of the two components, the pore size and the volume used - all these parametres are varied countless times until the perfect foam composition is found. And there is no such thing as THE one foam for Touratech seats. An individual formula is developed for each model.

The exact shape of the seat core, which enables an ergonomically correct and comfortable seating position, is determined for each motorcycle model in a complex process.

Fitting the cover is the final step in the production of the seat. Experience and dexterity are required to apply the fabrics to the core in the best saddlery manner, taut and crease-free.

Several thousand Touratech seats per year are produced. Due to the high proportion of manual work, seven specially qualified employees are employed from the development and production of the tub and foam core to the saddlery.

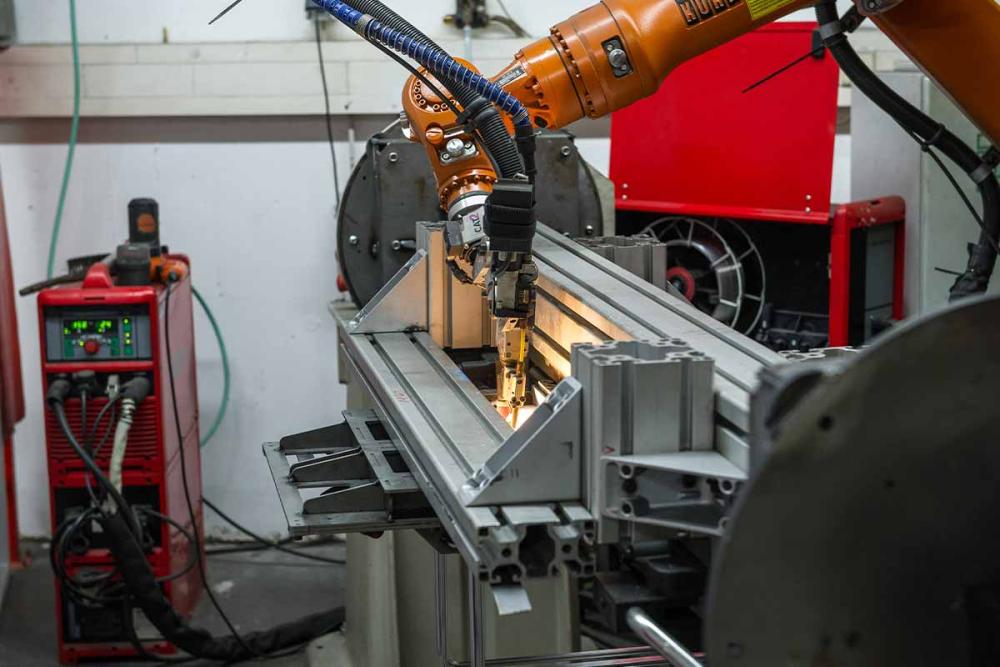

Welding Robots

With a new generation of welding robots, Touratech has once again significantly improved production quality and also taken a further step forward in the area of process reliability, which is particularly important for orders from OEM customers.

The new welding cells were developed as a joint project between Touratech and its partner company HAPPICH Production Technologies, which, like Touratech, is part of the Happich Group. Following joint project planning and requirements development, MEI implemented the robot technology, while the welding table supports with the further improved clamping systems are again Touratech‘s own developments.

A total of 11 welding robots are now in use in Touratech production. At least three systems are always used for aluminium welding, while the others are used for welding stainless steel constructions. Ideally, the systems run in a two-shift operation without downtime.

To ensure that the robots are used as efficiently as possible, Touratech uses a special IT system that precisely coordinates machine capacities, personnel resources and the scheduling of production. The programming of the welding robots requires a high level of qualification. In addition to basic programming experience, a sound knowledge of welding technology is required, so that a large number of well-trained specialists will also be needed in the future. The use of state-of-the-art robot technology thus fits seamlessly into Touratech‘s philosophy of manufacturing high-quality products economically at its headquarters in Niedereschach through the interplay of high-tech and excellently trained employees.

Hyrdoforming

Hydroforming offers developers and designers interesting possibilities for product design. When forming aluminium or stainless steel sheets, for example, the process allows almost arbitrarily small radii, and the repeat accuracy of the process is also very high. Particularly in the area of flat protectors, such as cylinder or engine guards, hydroforming enables complex shapes that guarantee a significant increase in protection.

However, in order to be able to use the process for the production of motorcycle accessories, the Touratech developers had to do pioneering work in many areas. This starts with work preparation, because cutting and preparing the sheet metal inserted into the machine, the so-called blank, is anything but trivial. Only if the blank is perfectly dimensioned can material flow out of the flange area to the exact extent required during the forming process.

And then there are the enormous pressures that have to be controlled in the device. Around 2,000 bar and more are required to form a four millimetre thick stainless steel blank.

Toolmaking, which requires extensive know-how, should also not be neglected in hydroforming. However, in contrast to classic deep drawing, only one half of the tool is required, which is one of the main advantages of the process. In Crew68 GmbH, Touratech has a long-standing partner on board who developed and implemented this process in-house in the early years.

Since 2023, Happich CZ s.r.o. has taken over the production of hydroforming products for Touratech GmbH in order to continue to manufacture perfect products for adventure riders in close cooperation with the capacities in laser cutting of aluminium and stainless steel components at Touratech in the Black Forest.