Around 750,000 aluminium panniers have been manufactured at Touratech to date. With the current ZEGA Evo model, the company is once again setting standards in terms of robustness and ease of use. We take a look at the making of an amazingly complex product.

It took the winner of the „ZEGA Evo Challenge“ a whole nine seconds to remove a pair of the brand new panniers from the motorcycle and reattach them. Touratech USA had organised the competition as part of the 2019 Touratech Rally to show how quickly and easily the new ZEGA Evo can be handled.

ZEGA Evo Challenge: The video of the competition is available at this URL: tourate.ch/EVOchallenge

How relevant the value of nine seconds is in practice, when you’re on the road, is open to debate. Nevertheless, it represents a turning point in the construction of aluminum motorcycle panniers. This is because the new mounting mechanism is the first to combine the convenience of a Quickmount system with the robustness required for extended off-road traveling. And numerous aspects of the pannier itself have been further improved.

„In the ZEGA Evo, we have focused all the experience we‘ve gained from 30 years of building aluminum panniers as well as from testing them under extreme conditions on countless occasions,“ says Jochen Schanz, who, as Chief Operating Officer (COO), is also responsible for any new developments at Touratech. „Only thanks to this unique wealth of experience is it possible to manufacture on a large-scale a product that places such high demands on dimensional accuracy and tolerance,“ he adds.

„We have concentrated all our know-how from 30 years of pannier production in the ZEGA Evo.“

Jochen Schanz, Touratech COO

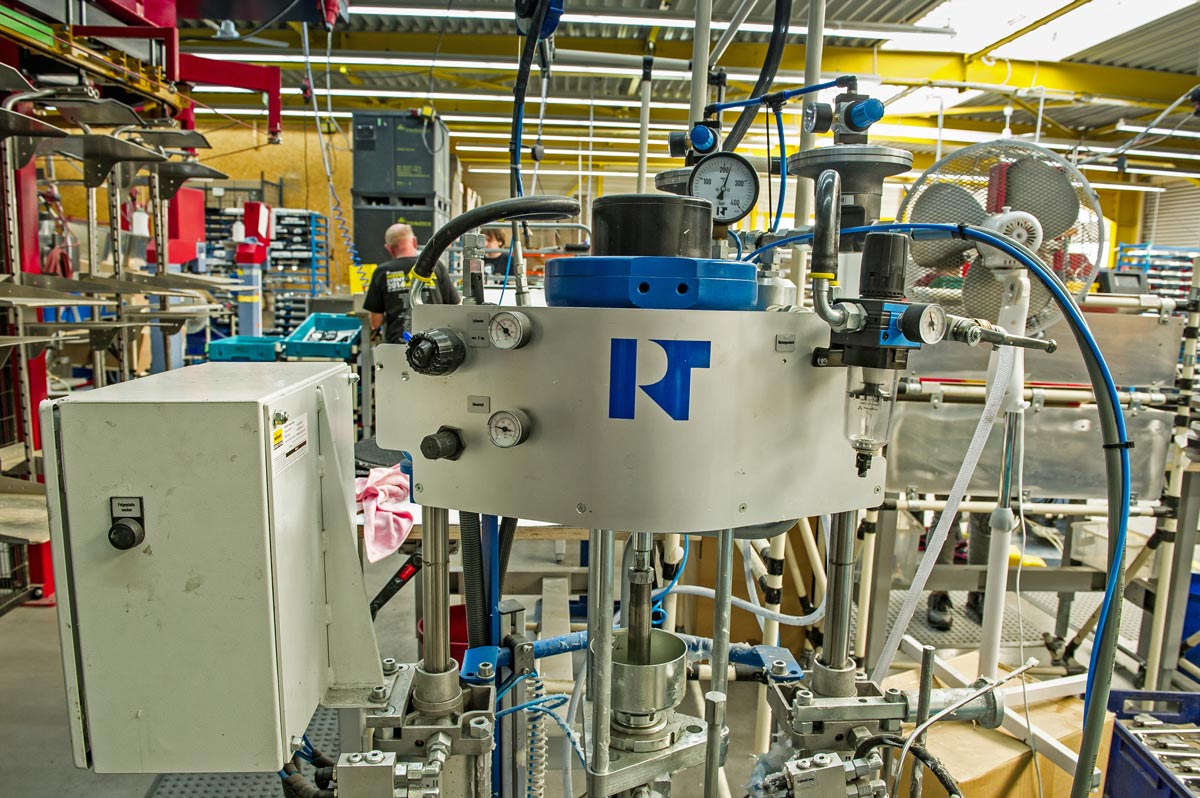

Along with the know-how of the developers, the second important pillar for the sustainable success of Touratech products is the permanent further development of the machinery. The high-tech machines Touratech uses for the production of the ZEGA Evo are at the cutting edge of technology.

Even the handling of the raw material is fully automated. This has less to do with saving on personnel and more to do with ensuring gentle transport of the scratch-sensitive sheets. The avoidance of damage - and the resulting rejects - characterises the entire further production process of the aluminium panniers. The decorative metal sheets have to pass through countless work steps - from cutting to size, through deep drawing of the lids and bases and welding of the pannier outer shell, to assembly - without the high-class surface suffering even the slightest damage.

Automatic transfer of parts from the bending robot.

The bending robot is reloaded with blanks.

The aluminium sheets are cut exclusively by laser. This applies to the sheet metal of the outer shell, where state-of-the-art flatbed lasers ensure precise outer geometries and hole patterns, as well as to the drawn bases and lids, which are precisely trimmed with a 3D laser after forming.

Just as the steps for machining the formed parts are bundled in an interlinked and fully automated machining cell, the most important steps for manufacturing the pannier shell are also processed in a fully automated machining centre. In this „outer shell processing cell“, the sheet metal is first bent, then stamped, and finally the joint is welded together by a welding robot. „A great deal of in-house development went into the outer shell processing cell,“ explains Jochen Schanz. Both the device for vertical bending - normally sheets are bent horizontally - and the linear welding machine for precise joining of the thin aluminium sheet had to be specially designed for the specific requirements of our pannier production,“ the manager adds.

This is how the ZEGA Evo is created

1. Cutting the sheet metal parts with the laser

2. Bending the outer shell in the production cell

3. Automated bending of base and lid (in this case a BMW pannier)

4. Riveting eyelets onto the lid of the ZEGA Evo.

5. Automatic dosing of adhesive

6. The base of the ZEGA Evo is sealed with a silicone sealing tape.

7. Application of the silicone seam with the dosing device

8. Drying tower with precisely determined temperature and humidity values

9. Fitting the mounting mechanism

10. Leak test

11. Assembly of the venting system

12. Careful final cleaning

13. The finished ZEGA Evo panniers…

14. …are packed for shipment.

15. Satisfied: Jochen Schanz and Michael Gnädig with a randomly selected pannier

Despite the high degree of automation, a large number of qualified employees are required for the production of the panniers. „To begin with, there‘s the operation and monitoring of our machining centres,“ Michael Gnädig, the production manager for pannier assembly goes on to explain. „And then there‘s the assembly of the individual components. This is where the highest precision is required,“ the 31-year-old industrial supervisor continues. The high demands on accuracy during assembly are a result of the sophisticated design of the pannier itself, which has a semi-floating base, for example. „This design, joined with special rivets, provides outstanding rigidity while minimising crack problems,“ adds Cliff Vizer, product development coordinator, who joined our manufacturing tour at short notice. Minimum tolerances are also required in the interaction between the pannier and the mounting mechanism, in order to ensure stable seating and flawless function.

Another challenge for the employees in the assembly department is the great variety of Touratech aluminium panniers. This means having to be particularly alert at all times.

To ensure that nothing goes wrong even with intensively trained employees, Touratech production has a close-meshed system of quality control. The checks range from permanent visual inspection after all relevant work steps, to the final tightness test. Each pannier is given an individual serial number with which the different steps can be traced back without interruption, so that any sources of error can be rectified immediately.

Thanks to precisely set temperature and humidity values, the silicone compound sets perfectly in the drying tower.

The automatic silicone dosing device.

In turn, employees are supported by numerous high-tech solutions. For example, the silicone is injected into the rebate in the exact quantity required by means of a dosing device. The demanding drying process for the sealing compound is also automated. „The silicone needs precisely defined temperature and humidity values in order to set optimally. We can accomplish this reliably in our drying tower, which the panniers pass through in a specified process time, fully automatically“ explains Michael Gnädig.

„What I appreciate about the ZEGA Evo is its superior „Made in Germany“ quality and the wide range of possible applications.“

Michael Gnädig, Production Manager Pannier Assembly

Thirty-two employees work in two shifts in the actual pannier production - around 130 colleagues if the production of the racks and attachments is included. Can this pay off in high-wage Germany? „Absolutely,“ says Jochen Schanz. „There are many good reasons for manufacturing the ZEGA Evo at the Niedereschach location. Here, we have extremely short distances and this, given the large quantities and high product volume, massively reduces logistics costs.“ The manager has a handy example of this: „With a daily output of up to 400 panniers, we handle about 60 pallet containers every day, just with outer shell components, here on the premises. That‘s the equivalent of two to three articulated lorries. With this volume to be handled, component production abroad is not economical“.

Added to this are the high quality requirements. „Except for the sourcing of the raw material, of course, and the manufacturing of some turned and plastic parts, the pannier manufacturing is all done in-house. This gives us access to every single step of the process, enabling us to ensure the highest possible quality,“ explains Jochen Schanz. „And we have a very close feedback loop from production to development, which means we can bring in improvements at short notice should there be any difficulties with individual production steps,“ adds Cliff Vizer.

„With the ZEGA Evo, the challenge was to develop a product that is better than anything that already exists. And the bar was already set very high by our own predecessor products.“

Cliff Vizer, Development management/Head of R&D

Thirty years after the ZEGA pannier brought the breakthrough in professional motorcycle aluminium panniers, the ZEGA Evo sets the standard once again in high-quality transport solutions for motorcycles. In the meantime, not only Touratech customers benefit from the unique competence of the Niedereschach-based company in the development and production of high-quality motorcycle panniers made of aluminium. Numerous premium manufacturers such as BMW, Ducati or KTM have panniers manufactured by Touratech for their own original accessories range. Touratech produces a total of around 100,000 panniers per year.

And the journey continues - not only for the hundreds of thousands of users of ZEGA panniers worldwide. The developers have numerous ideas up their sleeves for future pannier generations as well. „For us, the topic of adventure panniers is far from exhausted.“ That‘s all Jochen Schanz can reveal at the moment.

ZEGA Evo - The facts

- 1.5 millimetre thick aluminium sheet, silver or black anodised

Riveted corpus and base

Deep drawn lid and base

Robust lid profile with silicone seal

Impact resistant corner reinforcements

Recessed carrying handle made of webbing

New ergonomic catches

Catches with additional hinge function

Lid completely removable

New, easily removable lid safety strap

Improved ventilation

Completely new mounting and locking mechanism

Extensive equipment with attachment eyes, luggage hooks, accessory fastenings

Available in 31 | 38 | 45 litre volumes

Items 1 to 8 of 105 total